Journey from east to west – Transforming fibres to fabric

The journey of the clothes we wear is a fascinating one. The origin of the material, how it is grown and then converted from one form into another to produce the yarns, fabric and then garments, often holds an untold yet rich story. The complex relationships between nature – the land, weather, insects, plants and animals – and communities all over the world are connected with technological innovations and traditional craftsmanship in the supply chain. These transform precious natural materials into amazing products – and it’s an under-appreciated journey.

Sitting on bales of fibre, a spool of Khangai yak yarn and wearing the Tengri Chevron coat made of yak fabric.

The start of the journey – sourcing Khangai yak fibres

Mongolian yaks roam semi-wild, often at high altitudes. As indigenous animals, yaks graze gently on the steppes, living symbiotically within their natural ecosystem, allowing plant species and other wildlife to regenerate and thrive.

The Khangai mountains in western Mongolia are home to nomadic herder families who live off the land, and to an indigenous breed of yak only found in this region. The families move four to eight times a year to find good pastures for their animals. Research has revealed that because the yaks endure hot summers and cold winters (temperatures range between -40C and +40C), coupled with fluctuating day- and night-time micro-temperatures, they produce one of the softest Mongolian yak fibres. Even more prized are the rare, natural silver-coloured yak fibres.

Nomadic families in the east

In early spring and summer, the yaks begin to shed their winter coats. Working with a cooperative involving more than 4,500 nomadic herder families living in the Khangai region, I meet the cooperative’s leader to arrange an annual combing of the yaks. Each family corals their herd of yaks and each animal is individually hand-combed, producing a precious 100 grams of fibre, which is sold to Tengri at source, available only once a year.

Once each family has finished combing their yaks, the fibres are collected and bundled at the regional cooperative office. The herders organise a vehicle and drive the fibres across the country to the Mongolian capital, Ulaanbaatar.

The herders deliver the fibres to our designated partners in Ulaanbaatar, who wash the fibres in a gentle detergent, developed in England specifically for fine woollen fibres. The wet fibres are then put through a conveyor belt and through a large heating unit, from which the fibres emerge dry and collected, ready for hand-sorting into the different natural colours of the yak: silver, tan and cocoa.

Washing the fibres

Drying and sorting the fibres

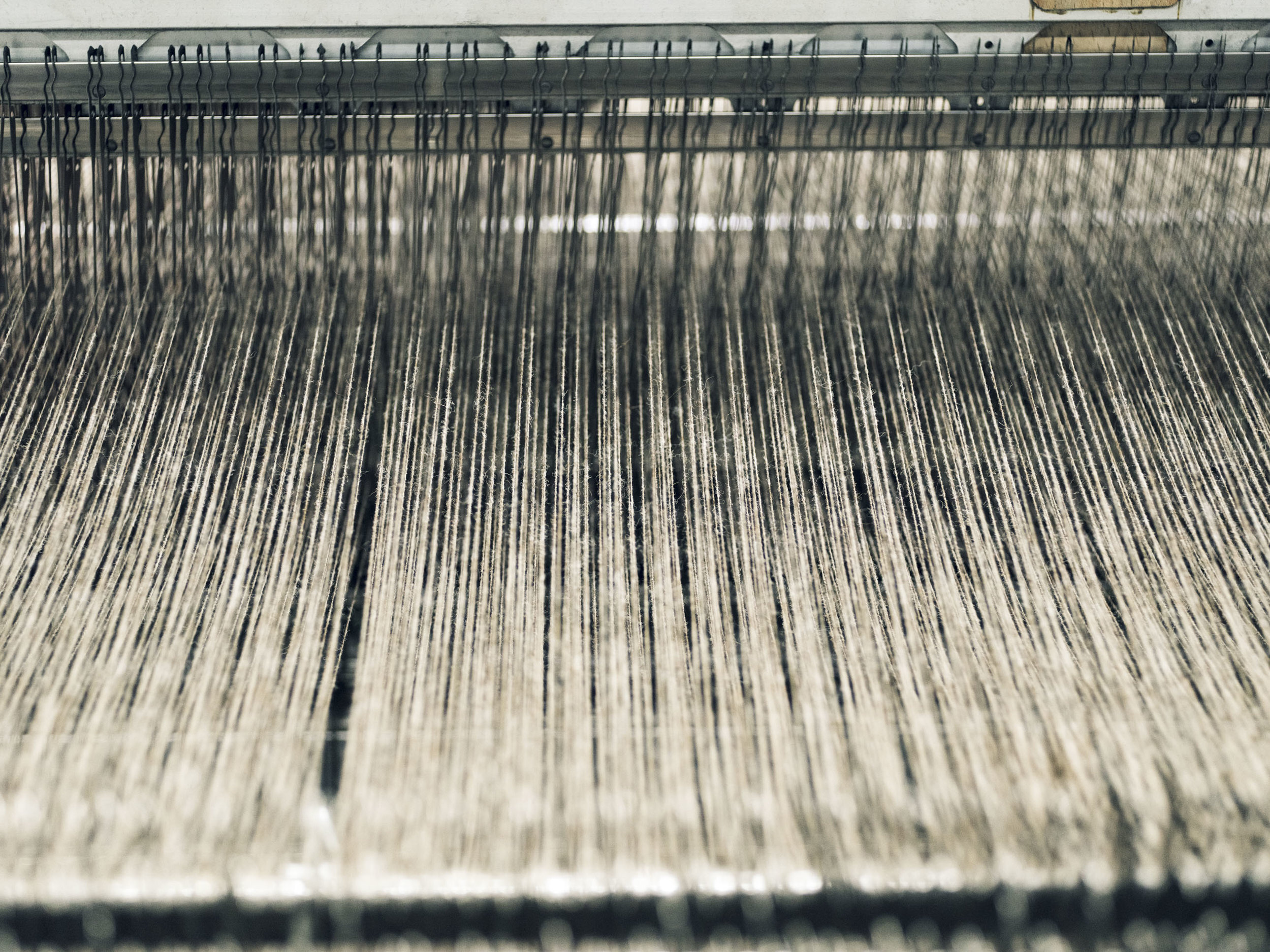

The fibres come in three grades: coarse, secondary and premium down. Because fibres are combed direct from each animal, a refining stage puts the fibres through large carding machines that comb out the different grades of fibres. The longer, coarse fibres are first to be filtered out and the softest, premium fibres are produced last. These are spun and woven into the finest yarns and fabrics.

Meet Peter Gledhill, who works with some of the world's leading textile experts to produce the finest cloth at his family mill. Take a look at this video to learn more about Peter's commitment to traditional craftsmanship and see how his company, R. Gledhill, helps to produce the premium yarns and fabrics for Tengri's collection. It's another vital stage of the global journey that transforms fibres into fabrics and connects communities around the world from east to west.

Photo credits: Nancy Johnston and Josh Exell © Tengri Ltd